#shot blasting

Explore tagged Tumblr posts

Text

Shot Blasting Machine

Shot Blasting Machine is a comprehensive platform dedicated to the field of shot blasting, offering a wide array of solutions for surface preparation and treatment needs. The website serves as a resourceful hub for businesses and individuals seeking high-quality shot blasting machines, abrasives, and related equipment.

With a focus on durability and efficiency, the platform features innovative technologies designed to enhance surface finishing processes, including cleaning, strengthening, and polishing metal surfaces. Additionally, ShotBlasting.org.in provides detailed information about various shot blasting techniques, equipment maintenance, and the latest advancements in the industry. Whether you are looking for professional-grade shot blasting solutions or technical guidance, this website is a reliable destination to meet all your surface preparation requirements.

0 notes

Text

Case Study: How a Shot Blasting Machine Transformed an Industrial Facility

In an ever-evolving industrial landscape, efficiency, precision, and productivity remain pivotal for staying competitive. At Ambica Enterprises, we take pride in empowering businesses with advanced solutions tailored to specific operational needs.

This case study reveals how a shot blasting machine not only revolutionized productivity but also introduced unprecedented levels of surface finishing precision in an industrial facility that struggled with manual cleaning and surface preparation processes.

Background: Challenges in Surface Preparation

The facility in question, a high-output manufacturing plant, faced persistent challenges related to surface preparation. With heavy workloads and diverse metallic surfaces requiring cleaning and texturing, the facility encountered issues such as:

Manual labor inefficiencies leading to increased operating costs

Inconsistent surface finishes, affecting product quality and customer satisfaction

Slow processing times that limited production output and delayed timelines

High wear and tear on equipment due to abrasive materials used in traditional methods

The company’s search for a solution led them to Ambica Enterprises, seeking a technological leap that could streamline operations and deliver consistent, high-quality results. After assessing their needs, we recommended a high-capacity automatic shot blasting machine equipped to handle large volumes and ensure a uniform finish.

Solution: The Power of Shot Blasting Technology

Ambica Enterprises provided a state-of-the-art automatic shot blasting machine, designed to meet the rigorous demands of high-output facilities. Our solution centered on:

Automation and Efficiency Automated systems significantly reduced the reliance on manual labor. Operators were required solely for setup and monitoring, while the machine's automated feeding and control mechanisms handled the blasting process seamlessly. This shift allowed the facility to reallocate resources, focusing manpower on quality control and other high-value tasks.

Precision Surface Finishing The precision of shot blasting allowed for a uniform, controlled abrasion across all metallic surfaces, resulting in an ideal preparation for subsequent painting or coating. Unlike manual methods that risk inconsistencies, the shot blasting machine delivered a consistent surface profile, critical for ensuring the adhesion of coatings and extending product longevity.

Reduction in Material Waste and Costs The shot blasting machine incorporated recyclable abrasives, dramatically reducing material consumption. Additionally, the closed system design minimized abrasive waste, cutting down on operational expenses tied to the replacement and disposal of materials.

Enhanced Processing Speeds By integrating automated shot blasting technology, the facility saw a 45% reduction in processing time. Faster throughput translated into shorter lead times, allowing the company to meet customer demands with ease. This speed not only improved productivity but also elevated customer satisfaction as orders were fulfilled more rapidly.

Key Benefits Observed After Implementation

Implementing the shot blasting machine transformed the facility’s daily operations. Here are the primary benefits realized:

1. Superior Surface Quality

The precision capabilities of our shot blasting machine provided a level of surface quality that was previously unattainable. Products achieved a smooth, even finish, which became crucial for applications requiring exact specifications in paint and coating adherence.

2. Significant Time Savings

Before implementing the machine, surface preparation was time-consuming and labor-intensive. Post-installation, the automated operation reduced surface preparation times significantly, allowing the facility to increase its daily production output without compromising quality.

3. Reduced Operational Costs

The transition to automated shot blasting yielded financial advantages, especially through reduced labor and material costs. The machine’s recyclable abrasive system and minimal maintenance needs translated into lower operating expenses, increasing the overall profitability of the facility.

4. Improved Worker Safety

Manual blasting processes often expose workers to airborne dust and harsh abrasives, posing risks to their health. With the enclosed, automated shot blasting system, the facility ensured a safer work environment, reducing employee exposure to potential hazards.

Technical Specifications of the Solution

To meet the facility’s high standards and workload requirements, Ambica Enterprises configured the shot blasting machine with the following specifications:

Abrasive Material: Steel grit, chosen for its longevity and effectiveness in removing rust, scale, and other surface impurities.

Blasting Chamber Size: Designed to accommodate larger parts while ensuring thorough coverage across complex geometries.

Control Panel: An intuitive control panel enabled operators to adjust blasting intensity and duration, tailoring the process to specific material needs.

Dust Collection System: An advanced filtration system that effectively contained dust and fine particulates, preserving air quality within the facility.

Recyclable Media System: The machine’s abrasive media recycling feature enabled repeated use of materials, minimizing both waste and supply costs.

Also Check - Automatic Sand Blasting Machine

Performance Metrics: Measuring the Impact

To gauge the machine’s impact, we tracked several key performance metrics over six months post-installation:

Production Throughput: Increased by 60% as processing times shortened and consistent quality was achieved across all units.

Cost Efficiency: Reduced overall production costs by 35%, attributed to lower material and labor expenses.

Quality Compliance: Customer complaints related to surface imperfections decreased by 70%, underscoring the improvement in finish quality.

Employee Safety: Incidents related to dust inhalation or abrasive injuries were reduced to zero, a testament to the machine’s enclosed design and filtration capabilities.

Customer Feedback and Satisfaction

Upon reviewing the initial results, the facility’s management expressed high satisfaction with the transformation enabled by the shot blasting machine. Not only did it optimize production, but it also strengthened the company’s ability to meet stringent industry standards. Here is a snapshot of the feedback shared by the management:

"Ambica Enterprises’ shot blasting machine has been a game-changer for our operations. We’ve seen efficiency levels soar, and our products now meet a quality standard we once struggled to achieve. The automation has freed up our team to focus on innovation rather than routine tasks. We are now able to fulfill customer orders faster and at a higher quality than ever before."

Why Choose Ambica Enterprises for Shot Blasting Solutions?

Ambica Enterprises is committed to delivering top-of-the-line shot blasting technology tailored to the unique needs of each facility. Our expertise, extensive product range, and focus on quality make us a trusted partner for industrial businesses seeking to elevate their operations. Choosing Ambica means:

Comprehensive Support: From initial consultation to after-sales service, our team ensures you maximize the benefits of your shot blasting equipment.

Customization: We tailor each machine to fit specific production demands, guaranteeing that your operational goals are met.

Sustainable Practices: Our machines promote environmental responsibility through recyclable abrasive media systems and efficient dust collection, contributing to greener industrial operations.

Conclusion

In this case study, we have highlighted the transformative power of Ambica Enterprises’ shot blasting machine and the measurable impact it had on an industrial facility's productivity, cost savings, and product quality. This project exemplifies our commitment to equipping industries with advanced technology solutions that drive sustainable growth and competitive advantage.

Investing in shot blasting technology from Ambica Enterprises isn’t just about purchasing a machine—it’s about committing to innovation, efficiency, and excellence in every product. For companies looking to redefine their manufacturing processes, our shot blasting solutions provide an essential foundation for consistent quality, operational savings, and growth.

0 notes

Text

Comparing Sandblasting and Shot Blasting: Which is Right for Your Project?

Introduction

When it comes to surface preparation and cleaning, both sandblasting and shot blasting are popular methods. Each has its unique advantages and applications, making the choice between them dependent on specific project requirements. In this blog post, we’ll compare sandblasting and shot blasting to help you determine which method is best suited for your needs.

Understanding Sandblasting

Sandblasting involves using a high-pressure stream of abrasive material, typically sand, to clean and smooth surfaces. It’s commonly used for removing rust, paint, and other contaminants from metal, wood, and concrete surfaces. The abrasiveness of the material makes it highly effective for tough cleaning jobs.

Understanding Shot Blasting

Shot blasting, on the other hand, uses spherical shots made of steel, glass, or ceramic to achieve a similar result. The shots are propelled at high speeds to clean, polish, or strengthen surfaces. This method is particularly favored in industrial applications where a high-quality finish and surface integrity are critical.

Key Differences Between Sandblasting and Shot Blasting

Abrasive Material:

Sandblasting: Uses angular abrasive materials like sand, which can be more aggressive on surfaces.

Shot Blasting: Uses spherical shots that are gentler on surfaces, reducing the risk of damage.

Surface Impact:

Sandblasting: Ideal for heavy-duty cleaning and removing tough contaminants.

Shot Blasting: Provides a smoother finish, making it suitable for delicate surfaces and applications requiring high precision.

Recycling of Abrasives:

Sandblasting: Abrasives like sand are typically single-use, leading to higher material costs.

Shot Blasting: Shots can be recycled multiple times, making the process more cost-effective.

Applications:

Sandblasting: Commonly used for paint and rust removal, surface preparation for coatings, and cleaning concrete.

Shot Blasting: Used for peening (strengthening) metal parts, deburring, deflashing, and creating a uniform surface finish.

Environmental and Safety Considerations:

Sandblasting: Generates a significant amount of dust, requiring proper ventilation and protective equipment.

Shot Blasting: Produces less dust, but safety precautions are still necessary to protect against flying shots.

Choosing the Right Method for Your Project

When deciding between sandblasting and shot blasting, consider the following factors:

Surface Material: Delicate surfaces may benefit more from shot blasting, while tougher materials can withstand the abrasiveness of sandblasting.

Desired Finish: If a smooth, polished finish is required, shot blasting is the better option.

Project Scale and Budget: Shot blasting may have higher initial equipment costs but can be more economical in the long run due to the recyclability of the shots.

Environmental Concerns: Consider the dust production and potential need for containment when choosing sandblasting.

Conclusion

Both sandblasting and shot blasting are effective methods for surface preparation and cleaning, each with its distinct advantages. Understanding the differences between them can help you make an informed decision based on your project’s specific requirements. Whether you need the aggressive cleaning power of sandblasting or the precision and finish of shot blasting, selecting the right method

0 notes

Text

What is the purpose of a shot blasting machine?

The best possible results in the finishing and surface preparation industries require cutting-edge technology, and one of the most essential tools can be the shot blasting equipment. Here at Process & Systems, a leading shot blasting machine manufacturer in Kolkata, India we understand the vital role the machines perform in increasing the quality and longevity of various products in different industries.

Understanding the Essence of Shot Blasting

Shot blasting refers to a process of surface treatment that involves the propelling of abrasive particles at high speeds on a surface. The goal is simple: to eliminate scale, dirt, and rust, as well as other undesirable substances, from the surface of the material, leaving a clean and polished surface. Shot blasting machines are an unnoticed star of this process that is designed to guarantee optimal performance in different applications.

Key Applications of Shot Blasting Machines

Surface cleaning and preparation: The primary function of a shot blasting machine is to remove dirt and clean surfaces. It could be removing the rust off of metal components, cleaning automobile parts, or preparing surfaces to be coated or painted. Shot blasting machines provide an uncontaminated and clean surface, which improves the overall appearance and quality of the finished product.

Deburring and Deflashing: Manufacturing flashes and burrs on metal components could compromise both the appearance and function. Shot blasting machines are excellent in removing imperfections and producing perfectly smooth products.

Shot Peening to Strengthen: Another important function of blasting equipment includes shot peening. It is a procedure that gives the strength of a metal component. This is especially important for the automotive and aerospace industries, in which structural integrity is an essential element.

Aerospace Industries: Precision is a must for the aerospace industry, which is why shot blasting machinery plays an important function in achieving the desired quality of surface finish for aircraft parts. They are able to prepare surfaces for further processes and ensure the highest levels of performance and safety.

Foundry and Automotive Industries: Foundries, as well as automotive manufacturing facilities, rely on shot blasting for cleaning and preparing different components. It doesn't matter if it's forgings, castings, or engine components; shot blasting machines are essential to the manufacturing of durable and high-quality products.

The Role of Shot Blasting Machine Manufacturers

The smooth functioning of the shot blasting equipment lies in the knowledge of shot blasting manufacturers. These companies specialize and manufacture machines that meet the particular requirements of different industries. From determining the right dimension and design of the machine to choosing the best abrasive material, manufacturers are crucial in improving the efficiency and effectiveness of shot blasting procedures.

Customization for Diverse Applications

Shot blasting machine makers are aware of the various requirements of their customers. No matter what the size of the workshop or massive industrial facility is, they make machines that are compatible with the requirements of customers. This kind of personalization increases the versatility of shot blasting equipment across different industries, resulting in their widespread use.

Technological Advancements

In the age of rapid technological advancements, manufacturers of shot-blasting machines are on the cutting edge of innovation. Automation integration, advanced control systems, and safety functions are just a few of the most important innovations that improve the efficiency and usability of machines. As the industry changes, manufacturers strive to remain at the forefront and ensure that their equipment remains up-to-date.

Conclusion

The function of a machine for shot blasting goes beyond its surface. It is the foundation for the pursuit of excellence in industrial manufacturing. Process & Systems, with its unwavering dedication to innovation and quality, is an example to follow in the industry, providing cutting-edge solutions for shot blasting and a dependable shot blasting equipment supplier as well as spare parts distributor. As industries change and demand greater standards for quality and efficiency, Process & Systems remains at the forefront, helping companies to attain perfection and precision in the processing of surfaces.

0 notes

Text

Exploring the Power of Shot Blasting Machine India

Welcome to the fascinating world of Shot Blasting Machine India! In this post, we'll take you on a journey through the dynamic and ever-evolving landscape of shot blasting technology in India. From the bustling industrial hubs of Jodhpur to the picturesque landscapes of Gujarat, we'll uncover the pivotal role that Shot Blasting Machine India plays in shaping various industries across the country.

So, what exactly is a Shot Blasting Machine, and why is India making waves in this domain? Well, let's dive right in and explore the ins and outs of this powerful technology that's leaving an indelible mark on the manufacturing and construction sectors in India and beyond.

Understanding the Basics

Before we delve into the Indian perspective, it's crucial to grasp the fundamentals of shot blasting machines. These versatile machines are essentially used for surface cleaning, preparation, and finishing of various materials, including metal, concrete, and even wood. Shot blasting is a highly efficient and eco-friendly method, making it a sustainable choice for many industries.

What is Shot Blasting?

Shot blasting is a process that involves propelling small steel or abrasive particles, known as "shots," at high speeds to clean, roughen, or strengthen a material's surface.

The shots impact the surface and remove contaminants like rust, scale, paint, or dirt, leaving it clean and ready for further processing.

The Role of Shot Blasting Machines in India

India, a country with a rapidly growing industrial sector, is no stranger to innovation and technological advancements. Shot Blasting Machine India has found a significant role to play in a plethora of industries, and here's how:

1. Automotive Industry

The automotive sector in India is booming, and shot blasting machines play a crucial role in ensuring the quality and durability of various automobile components.

Shot blasting is used to clean and prepare engine parts, suspension components, and even entire vehicle chassis for painting, enhancing the longevity of these critical components.

2. Construction Industry

In the construction sector, shot blasting is utilized to clean and prepare concrete surfaces. It's a cost-effective and eco-friendly alternative to chemical cleaning methods.

Shot blasting is also employed for creating texture on roads and bridges to prevent skidding and improve safety.

3. Aerospace Industry

The aerospace industry demands impeccable precision and surface finish. Shot blasting machines are employed to clean and prepare aircraft components, ensuring they meet the stringent quality standards required for aviation.

4. Foundry and Forging

Shot blasting machines are used in the foundry and forging industry to clean and prepare metal castings and forgings. This process ensures a clean, defect-free surface before further machining or coating.

Shot Blasting Machine India - The Market Leader

When it comes to the shot blasting machine market, India is making remarkable strides and emerging as a leader in the field. This is not only due to the burgeoning manufacturing sector but also the innovative approach of Indian companies in developing cutting-edge shot blasting technology. What sets Shot Blasting Machine India apart? Let's find out!

1. Indigenous Manufacturing

India boasts a robust domestic manufacturing industry for shot blasting machines. Several renowned Indian manufacturers are producing high-quality machines that cater to diverse industrial needs.

Indigenous manufacturing not only boosts the local economy but also ensures easy availability and faster customer support.

2. Customization

Indian shot blasting machine manufacturers are known for their flexibility in customizing machines to suit specific requirements. Whether you need a machine for cleaning small components or large structural elements, Indian companies can tailor solutions to meet your needs.

3. Cost-Effective Solutions

Indian manufacturers offer cost-effective shot blasting solutions without compromising on quality. This affordability has made shot blasting technology accessible to a wider range of industries, including small and medium-sized enterprises. Also check - sand blasting machine

4. Robust After-Sales Support

The after-sales support provided by Indian manufacturers is top-notch. They offer maintenance services, spare parts, and technical assistance, ensuring that your shot blasting machines remain in optimal condition.

FAQs About Shot Blasting Machines in India

Let's address some common questions that might be on your mind:

Q1: Are shot blasting machines eco-friendly?

Absolutely! Shot blasting is an eco-friendly process as it uses recyclable abrasive shots and doesn't involve harmful chemicals, making it a sustainable choice for surface cleaning and preparation.

Q2: What industries benefit from shot blasting in India?

A wide range of industries in India benefit from shot blasting machines, including the automotive, construction, aerospace, foundry, and forging industries, among others.

Q3: Can shot blasting be used for rust removal?

Yes, one of the primary applications of shot blasting is rust removal. It effectively removes rust, scale, and other contaminants from metal surfaces, leaving them clean and ready for further processing.

Q4: Are Indian shot blasting machines of high quality?

Indian shot blasting machine manufacturers are known for producing high-quality machines that meet international standards. They offer robust after-sales support and customization options to cater to diverse needs.

Q5: What are the advantages of shot blasting over traditional cleaning methods?

Shot blasting is faster, more efficient, and environmentally friendly compared to traditional cleaning methods like chemical cleaning. It also provides a consistent and uniform surface finish.

The Future of Shot Blasting Machine India

As India continues its journey towards becoming a global manufacturing and industrial powerhouse, the future of Shot Blasting Machine India looks brighter than ever. The innovative spirit of Indian manufacturers, coupled with the increasing demand for sustainable and cost-effective surface preparation solutions, is set to drive further growth in this sector.

Advancements in Technology

Indian companies are investing in research and development to enhance shot blasting technology. This includes the development of more efficient and automated shot blasting machines that can handle larger workloads while reducing energy consumption.

International Collaborations

Indian manufacturers are increasingly collaborating with international partners to bring the latest technology and innovations to the country. This exchange of ideas and technology is sure to keep India at the forefront of the shot blasting industry.

Expansion into New Markets

Indian shot blasting machine manufacturers are eyeing global markets for expansion. Their reputation for providing quality products at competitive prices makes them strong contenders in the international arena.

Conclusion

In conclusion, Shot Blasting Machine India is a dynamic force that's driving progress in various industries across the country. With its eco-friendly and cost-effective solutions, Indian shot blasting technology is not only meeting domestic demands but also making a mark on the global stage.

The shot blasting industry in India is characterized by indigenous manufacturing, customization, cost-effective solutions, and robust after-sales support. These factors, combined with a focus on innovation and sustainability, are paving the way for a brighter future in the shot blasting sector.

So, if you're in the market for a shot blasting machine that offers quality, reliability, and affordability, look no further than the thriving world of Shot Blasting Machine India. It's not just a machine; it's a game-changer!

#shot blasting machine#shot blasting machine india#shot_blasting_machine#shot blasting#blasting machine#ambica enterprises

1 note

·

View note

Text

Corrosion Protection through Sand, Grit, and Shot Blasting

Introduction

Corrosion is a significant challenge faced by various industries, causing extensive damage to structures, equipment, and infrastructure. The prevention of corrosion is crucial to ensure the longevity and safety of these assets. Sand, grit, and shot blasting are effective surface preparation methods widely employed to mitigate corrosion by removing contaminants and creating a clean surface for protective coatings. In this article, we will delve into the benefits and applications of these abrasive blasting techniques in corrosion protection.

The best sandblasting services in Bangalore is one of the best surface preparation technology for steel surfaces for protecting steel from Corrosion.

Understanding Corrosion

Corrosion is a natural process of electrochemistry that occurs when metals react with their environment. Factors such as moisture, oxygen, chemicals, and temperature variations can accelerate this process. Corrosion leads to the deterioration of metal surfaces, compromising structural integrity, and potentially causing costly repairs or replacements.

The Role of Sand, Grit, and Shot Blasting

Sand, grit, and shot blasting are mechanical methods used to prepare surfaces for protective coatings, painting, or other surface treatments. These techniques involve forcibly propelling abrasive particles at high speeds onto the metal surface, effectively removing rust, old coatings, scale, and other contaminants. By doing so, they create a clean and profiled surface, significantly enhancing the adhesion of subsequent coatings, and thus, the overall corrosion protection.

Sand Blasting

Sandblasting is one of the oldest and most commonly used methods in corrosion protection. It involves propelling fine sand particles onto the metal surface using compressed air. The impact of sand particles effectively removes surface impurities, leaving behind a clean and roughened surface. Sandblasting is ideal for preparing large surfaces, such as ship hulls, bridges, and storage tanks.

Grit Blasting

Grit blasting is similar to sand blasting but uses a more substantial abrasive material like angular particles of steel grit. This method is highly effective in removing tough contaminants and creating a coarser profile on the metal surface. Grit blasting is commonly employed in industries such as aerospace, automotive, and construction, where more aggressive surface preparation is necessary.

Shot Blasting

Shot blasting involves the use of metallic shots (usually steel) propelled at high velocity to clean and prepare metal surfaces. The shots impact the surface and bounce back into the machine's chamber, where they are recycled for reuse. Shot blasting is excellent for achieving a specific surface roughness, making it suitable for applications like preparing surfaces for powder coating or painting.

Advantages of Sand, Grit, and Shot Blasting in Corrosion Protection

Enhanced Coating Adhesion: The primary benefit of abrasive blasting techniques lies in the enhanced adhesion of protective coatings. A clean and roughened surface ensures that the coating adheres firmly to the metal, reducing the risk of delamination and enhancing its durability.

Efficient Rust Removal: Sand, grit, and shot blasting are particularly effective in removing rust and corrosion from metal surfaces. By eliminating these corrosive elements, the blasting process impedes further damage and helps extend the asset's lifespan.

Cost-Effectiveness: While abrasive blasting requires an initial investment in equipment and expertise, it proves to be cost-effective in the long run. By preventing corrosion-related damages and reducing maintenance requirements, it saves significant expenses over time.

Versatility: Sand, grit, and shot blasting can be adapted to various surfaces, shapes, and sizes. Whether it's a small, intricate component or a large industrial structure, these methods can be tailored to suit the specific needs of the project.

Environmentally Friendly: The use of abrasives like sand and steel shots is environmentally friendly compared to chemical methods. These abrasives are reusable, and the process generates less waste, making it a sustainable choice for corrosion protection.

Applications of Sand, Grit, and Shot Blasting

Maritime Industry: Ship hulls and maritime structures are highly susceptible to corrosion due to constant exposure to saltwater. Sand and grit blasting are commonly used to prepare the surfaces for anti-corrosive coatings, extending the life of vessels and maritime infrastructure.

Oil and Gas Sector: In the oil and gas industry, pipelines, storage tanks, and drilling equipment are at risk of corrosion from harsh environments. Shot blasting is often employed to ensure effective surface preparation for protective coatings in this sector.

Infrastructure Maintenance: Bridges, highways, and buildings are exposed to the elements, making them prone to corrosion. Grit blasting is widely used to maintain and protect the structural integrity of these assets, reducing the need for frequent repairs.

Conclusion

Corrosion protection is a critical aspect of maintaining the integrity and durability of metal structures and equipment across various industries. Sand, grit, and shot blasting are proven and effective methods for surface preparation, ensuring optimal adhesion of protective coatings and hindering corrosion progression. By utilizing these abrasive blasting techniques, industries can significantly extend the life of their assets and reduce long-term maintenance costs while promoting sustainability and environmental responsibility.

#sandblasting#gritblasting#shot blasting#surface preparation#sandblasting services#sandblasting services in bangalore

0 notes

Photo

Surface International Introducing new outlet on Shot Blasting Machine. We are top leading shot blasting machine manufacturers and suppliers in India. This outlet explains the brief information on shot blasting machine. Get in touch with us for more details.

#Shot Blasting Machine#shot blasting machine manufacturer#shot blasting machine suppliers in India#shot blasting#Technology

0 notes

Text

What is Shot Blasting, and which is the Best Company for Shot Blasting in Eastern India?

Shot blasting is a surface preparation technique used to clean, polish, or strengthen various materials. It involves propelling abrasive materials, such as steel shots or grits, at high speeds onto the surface to remove contaminants, scale, or old coatings. Shot blasting is commonly employed in industries like construction, automotive, and aerospace for applications like rust removal, surface texturing, and preparation for painting or coating.

When it comes to the Best Shot Blasting Company in Eastern India, one prominent name that stands out is Datre Shot Blasting Services. Datre Corporation Ltd. is Top Shot Blasting Company in India. With their expertise and state-of-the-art equipment, they have earned a solid reputation in the region. Datre Shot Blasting Services is known for their commitment to quality, adherence to strict industry standards, and timely completion of projects. They offer a wide range of shot blasting services tailored to meet the specific needs of their clients. Their team of skilled professionals ensures efficient and precise surface preparation, delivering excellent results.

Whether you require shot blasting for industrial or commercial purposes, Datre Shot Blasting Services in Eastern India is a reliable choice due to their experience, technical capabilities, and dedication to customer satisfaction.

Company name: Datre Corporation

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#shot blasting#shot blasting manufacturer#steel casting manufacturer#manufacturing industry#manufacturing company#aluminium manufacturer#manufacturer#datre corporation

1 note

·

View note

Text

Efficient Movement and Storage of Goods The Basics of Materials Handling

Materials handling is an integral part of modern industrial operations. The term refers to the movement, storage, control, and protection of materials and products within a manufacturing, distribution, or warehousing facility. Effective materials handling is essential for reducing costs, improving productivity, and ensuring a safe working environment. In this article, we will explore the importance of materials handling and some of the key strategies for optimizing this critical function.

Why are Materials Handling Important?

Effective Materials Handling can have a significant impact on the bottom line of any industrial operation. One of the key benefits of Materials Handling is increased efficiency. By streamlining the movement of materials, organizations can reduce the time and resources required to move products from one place to another. This, in turn, can lead to faster turnaround times, improved productivity, and lower costs. Another important benefit of materials handling is improved safety. By implementing proper materials handling procedures, organizations can minimize the risk of workplace injuries and accidents. This is particularly important in industries where heavy machinery and equipment are used, such as manufacturing and construction. Finally, materials handling is essential for maintaining product quality. Improper handling can damage products or cause them to become contaminated, leading to costly rework or even product recalls. By implementing proper Materials Handling procedures, organizations can ensure that products are delivered to customers in the best possible condition.

Strategies for Optimizing Materials Handling

There are several key strategies that organizations can use to optimize their materials handling processes. These include:

Standardization: Standardization involves developing consistent processes and procedures for materials handling. By standardizing processes, organizations can reduce variability and ensure that materials are handled consistently across all operations. This can lead to improved efficiency, reduced errors, and better quality control.

Automation: Automation involves the use of technology to automate materials handling tasks. This can include the use of conveyor belts, robotics, and other automated systems to move materials throughout a facility. By automating materials handling tasks, organizations can improve efficiency, reduce costs, and minimize the risk of workplace injuries.

Ergonomics: Ergonomics involves designing materials handling processes and equipment to reduce the risk of workplace injuries. This can include the use of ergonomic lifting devices, such as hoists and lift tables, to reduce the risk of back injuries. By implementing ergonomic materials handling practices, organizations can improve worker safety and reduce the risk of workplace injuries.

Lean Principles: Lean principles involve reducing waste and improving efficiency in all aspects of operations. This can include the use of just-in-time (JIT) inventory systems, which help organizations to reduce inventory levels and improve efficiency. By implementing lean principles in materials handling, organizations can reduce waste, improve efficiency, and lower costs.

Training: Training is essential for ensuring that employees understand proper materials handling procedures and are equipped with the skills and knowledge needed to perform their jobs effectively. This can include training on proper lifting techniques, the use of equipment, and safety procedures. By providing training to employees, organizations can improve safety, reduce errors, and improve productivity.

Conclusion

Materials handling is a critical function in modern industrial operations. Effective materials handling can have a significant impact on the efficiency, safety, and quality of products. By implementing strategies such as standardization, automation, ergonomics, lean principles, and training, organizations can optimize their materials handling processes and improve their bottom line. As the world becomes increasingly reliant on efficient and effective supply chains, materials handling will continue to be a critical function in the success of modern businesses.

0 notes

Text

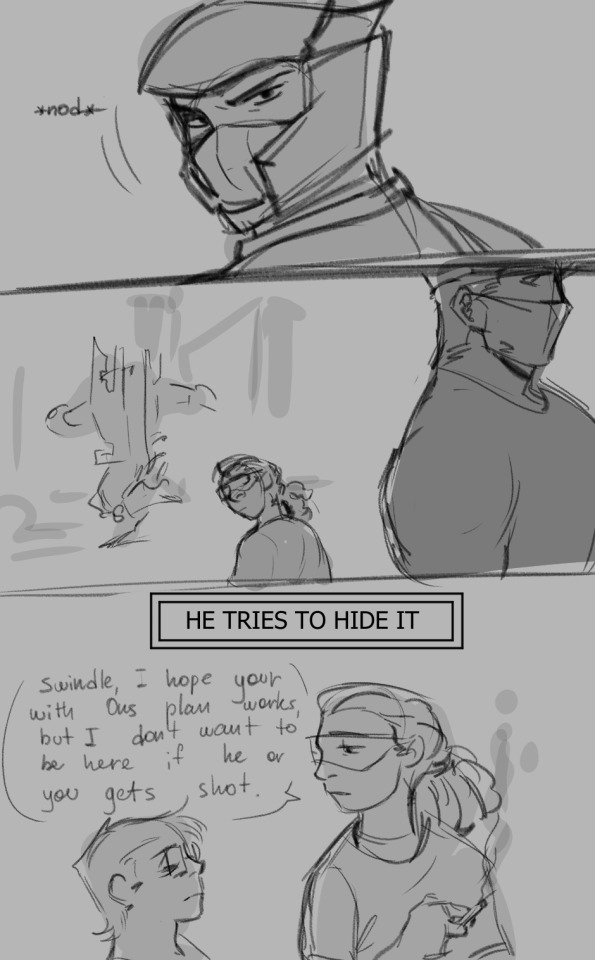

@keferon BITING YOU FOR ADDING THIS BIT. I DIDN'T LIKE HOW THEIR PATH WENT IN IDW. YOU JUST WENT AND SAID "Who needs Starscream, Onslaught might find it out by himself" AND I EXPLODED

#LISTEN I REALLY LOVE THESE TWO#The fact that Blast Off didn't like to see how Onslaught was slowly reaching the point of no turn back where he will end up getting shot#If I remember correctly it is one of the main reasons why he agreed to Starscream's plan#Bullshitting but... I've lost my thought...#I need to go sleep#cockroachdoodles#tf mecha universe#humanformers#blast off#onslaught#ahhh.... others...#jazz#swerve#swindle#Please no one look at me I am dead#combaticons#on/off

757 notes

·

View notes

Text

Top Sandblasting Machine Manufacturers & Suppliers in India

Find the best sand blasting machine manufacturers and suppliers in India offering high-quality and durable equipment for various industrial applications. These machines ensure efficient surface preparation, cleaning, and finishing. Trusted for their reliability and performance, they cater to industries like construction, automotive, and manufacturing. Choose from portable, cabinet-type, or automatic sandblasting machines to suit your needs.

0 notes

Text

Understanding the Environmental Impact of Shot Blasting

In recent years, industries worldwide are increasingly aware of their environmental impact and the need for sustainable practices. In this context, shot blasting—a method widely used in manufacturing, construction, and various industries—has become a focus for environmental evaluations. This article delves into the environmental effects of shot blasting, the methods for reducing its footprint, and the role of Ambica Enterprises in pioneering eco-friendly shot blasting solutions.

What is Shot Blasting?

Shot blasting is a surface preparation technique used to clean, polish, and strengthen surfaces by propelling abrasive materials, often steel shots or grits, at high speeds onto the target material. This process is widely used for rust removal, surface profiling, and metal cleaning. Although effective and efficient, it is essential to understand and mitigate its environmental impacts.

Key Environmental Impacts of Shot Blasting

1. Dust and Airborne Particulate Matter

The shot blasting process generates dust and fine particulate matter that can contaminate air quality. In facilities without proper ventilation systems, these particulates may contain heavy metals and other contaminants, potentially impacting workers’ health and the local environment.

Air Quality Concerns: Unchecked, this dust can contribute to air pollution, leading to potential respiratory issues among workers and nearby communities.

Waste Management Challenges: Accumulated dust often requires careful handling and disposal to prevent soil and water contamination.

2. Energy Consumption and Carbon Footprint

Shot blasting machines are typically energy-intensive, contributing to the overall carbon footprint of industrial operations. The process consumes electricity or fuel, resulting in carbon dioxide (CO₂) emissions. These emissions contribute to climate change unless steps are taken to improve the energy efficiency of the machines.

Reducing Carbon Emissions: Using machines with optimized energy efficiency or renewable energy sources can mitigate these emissions.

3. Waste Abrasives and Material Disposal

Shot blasting generates a significant amount of waste abrasives. Traditional materials like sand and grit are single-use and must be disposed of afterward, often in landfills. Even reusable media like steel shots degrade over time, creating waste that must be managed appropriately.

Environmental Burden of Waste Disposal: Disposing of spent abrasive media improperly can contribute to soil and water pollution.

Recycling Opportunities: Recycling used abrasives can help reduce the waste burden and minimize the environmental impact of material disposal.

4. Noise Pollution

The high-velocity blasting process produces loud noise, potentially exceeding OSHA noise limits for industrial settings. Noise pollution can affect not only the health of workers but also disturb surrounding areas, especially if the facility is near residential zones.

Solutions for Noise Reduction: Implementing acoustic barriers or using low-noise machines can help reduce the noise pollution associated with shot blasting operations.

Strategies for Minimizing the Environmental Impact of Shot Blasting

1. Utilizing Environmentally Friendly Abrasives

Switching to eco-friendly abrasives, such as natural or biodegradable materials, can substantially reduce the environmental impact of shot blasting. While traditional metallic abrasives like steel shots are commonly used, newer organic media can perform effectively while reducing environmental contamination.

2. Adopting Advanced Filtration and Dust Collection Systems

Efficient dust collection systems are critical for minimizing the release of airborne particles into the environment. HEPA filters and multi-stage dust collectors capture fine particles before they can spread, enhancing air quality and worker safety.

Closed-Loop Systems: These systems capture and recycle air within the blasting chamber, reducing the need for external ventilation and minimizing airborne pollutants.

3. Recycling and Reusing Abrasives

Abrasive recycling is an effective strategy for reducing waste. Reusable abrasives like steel shots can go through multiple cycles, reducing the need for new material and the environmental footprint of disposal.

Automated Recovery Systems: Such systems can recover spent abrasives automatically, separating debris and contaminants for disposal while sending reusable media back into the blasting cycle.

4. Upgrading to Energy-Efficient Equipment

Switching to energy-efficient shot blasting machines not only cuts down on electricity costs but also reduces the carbon footprint associated with high energy consumption. Machines designed with automated controls optimize the use of energy based on the requirements of each job, preventing unnecessary energy usage.

5. Implementing Water-Based Blasting Alternatives

Some applications now offer water-based blasting systems that reduce dust and the need for traditional abrasive materials. Though not suitable for all shot blasting needs, this method can be effective for outdoor applications and situations where dust suppression is crucial.

Hybrid Systems: Hybrid shot blasting machines that combine wet and dry blasting can be particularly useful in minimizing environmental impact while retaining versatility across different applications.

Ambica Enterprises: Committed to Sustainable Shot Blasting Solutions

At Ambica Enterprises, we are dedicated to providing environmentally conscious solutions that support sustainability without compromising efficiency. With a strong emphasis on innovation and green technology, our machines and equipment are designed to meet stringent environmental standards while delivering the exceptional performance our clients require.

Our Eco-Friendly Shot Blasting Initiatives

Energy-Efficient Machines: Our equipment is built to consume 30% less energy than traditional shot blasting systems, reducing carbon emissions and lowering operational costs.

Advanced Dust Collection Technology: We integrate multi-stage filtration systems that capture and contain dust effectively, helping maintain clean air standards and workplace safety.

Sustainable Abrasive Options: We offer solutions for customers interested in using recycled abrasives, ensuring that waste production is minimized while upholding the same cleaning power.

Recycling Programs: We facilitate recycling for spent abrasives, particularly steel shots and grits, through partnerships with certified recycling facilities. This reduces the burden on landfills and supports sustainable industrial practices.

Also Check - Shot Blasting Machine Manufacturers

Future of Sustainable Shot Blasting: Industry Trends

1. Advancements in Automated and Closed-Loop Systems

Automation is transforming the industry by enabling precise control over the shot blasting process, which minimizes waste and optimizes energy consumption. Closed-loop systems are expected to become a standard, ensuring that dust, noise, and waste are controlled at the source.

2. Increasing Use of Artificial Intelligence for Efficiency

AI-powered shot blasting systems can analyze surfaces in real time, adjusting settings to maximize effectiveness with minimal abrasive usage. This not only extends the life of the abrasives but also reduces the waste and environmental impact of each blasting operation.

3. Expanding Demand for Biodegradable Abrasives

As sustainability continues to influence purchasing decisions, the demand for biodegradable abrasive media is likely to increase. These materials are especially useful for industries committed to eco-friendly practices.

4. Regulatory Push for Environmental Compliance

Governments and regulatory bodies worldwide are implementing stricter guidelines for air quality, waste management, and noise levels in industrial operations. Shot blasting companies are responding by adopting cleaner, more efficient processes, spurring further innovation in eco-friendly blasting technologies.

Conclusion

Shot blasting machine remains an essential process in multiple industries, yet its environmental impact cannot be ignored. By understanding the sources of environmental stress and adopting sustainable practices, companies can significantly reduce their footprint. At Ambica Enterprises, we are at the forefront of this transformation, offering energy-efficient, eco-conscious shot blasting solutions designed for today’s environmentally aware world.

For businesses committed to sustainability, investing in eco-friendly shot blasting can align operational goals with environmental responsibility. As technologies evolve, the shot blasting industry is poised to become greener, more efficient, and increasingly aligned with the principles of sustainable manufacturing.

0 notes

Text

The Future of Surface Preparation: Advancements in Sandblasting and Shot Blasting Technology

As industries continue to evolve and demand higher standards of efficiency, quality, and environmental responsibility, the field of surface preparation, including sandblasting and shot blasting, is poised for further advancements. In this blog post, we'll explore one more key aspect shaping the future of sandblasting and shot blasting: integration with digital technologies.

Digitalization and Smart Solutions:

The integration of digital technologies, including sensors, data analytics, and automation, is revolutionizing the way sandblasting and shot blasting processes are conducted. Smart blasting systems equipped with sensors can monitor parameters such as pressure, flow rate, and surface roughness in real-time, allowing for precise control and adjustment of blasting parameters to optimize performance and quality.

Data analytics tools analyze the vast amounts of data generated during the blasting process to identify patterns, trends, and opportunities for process optimization. Machine learning algorithms can learn from past blasting experiences to improve efficiency, predict equipment maintenance needs, and optimize media consumption.

Furthermore, the connectivity enabled by the Internet of Things (IoT) allows for remote monitoring and control of blasting operations, providing operators with greater flexibility and visibility into their processes. Mobile applications and cloud-based platforms enable seamless communication and collaboration among stakeholders, streamlining project management and documentation.

The adoption of digitalization and smart solutions in sandblasting and shot blasting not only enhances operational efficiency and quality but also facilitates compliance with regulatory requirements and sustainability goals. By leveraging real-time data and predictive analytics, industries can minimize waste, reduce downtime, and achieve higher levels of productivity and profitability.

In conclusion, the future of sandblasting and shot blasting is characterized by the integration of digital technologies such as sensors, data analytics, and automation. These advancements promise to revolutionize surface preparation processes, offering greater precision, efficiency, and sustainability. By embracing digitalization and smart solutions, industries can stay ahead of the curve and meet the evolving demands of a rapidly changing world.

0 notes

Text

Portable Shot Blasting Machine Features | Ambica Enterprises

Welcome, fellow enthusiasts of surface preparation and restoration! Are you ready to embark on a journey through the innovative realm of portable shot blasting machines? Join us as we delve into the exceptional features offered by Ambica Enterprises, a leading name in the industry.

Exploring the Versatility

Portable Shot Blasting Machine Features boasts an array of features designed to cater to diverse surface preparation needs. Let's uncover the versatility that sets these machines apart!

Mobility at Its Best: With their compact design and sturdy wheels, Ambica's portable shot blasting machines ensure easy transportation across various job sites. Say goodbye to cumbersome setups and hello to effortless mobility!

Powerful Performance: Despite their portable nature, these machines pack a punch when it comes to performance. Equipped with robust blasting mechanisms, they deliver consistent and efficient results on a wide range of surfaces.

Adjustable Settings: Whether you're tackling delicate surfaces or heavy-duty projects, Ambica's machines offer adjustable settings to suit your specific requirements. From blast intensity to angle adjustments, you're in control of the outcome.

Dust-Free Operation: Concerned about dust and debris? Fear not! Ambica's shot blasting machines come equipped with advanced dust collection systems, ensuring a clean and safe working environment.

Key Features

Now, let's take a closer look at some of the standout features that make Ambica's portable shot blasting equipment a cut above the rest!

1. Precision Blasting

Achieve precise and uniform results with Ambica's precision blasting feature. Whether you're removing rust, paint, or contaminants, this feature ensures consistent coverage and impeccable finish every time.

2. Easy Maintenance

Say goodbye to downtime and maintenance headaches! Ambica's shot blasting machines are designed for easy upkeep, with accessible components and user-friendly maintenance procedures. Spend less time on maintenance and more time on getting the job done!

3. Ergonomic Design

Experience comfort and convenience like never before with Ambica's ergonomic design. From adjustable handles to intuitive controls, every aspect is engineered for maximum comfort and efficiency, reducing operator fatigue and enhancing productivity.

4. Environmental Friendliness

Concerned about environmental impact? Ambica's shot blasting machines are engineered with sustainability in mind. With efficient abrasive consumption and low emissions, you can rest assured knowing that you're making a positive contribution to the environment.

FAQs

Curious minds, rejoice! Here are some frequently asked questions about Portable Shot Blasting Machine Features | Ambica Enterprises:

Q1: Can these machines handle heavy-duty applications?

Absolutely! Ambica's shot blasting machines are designed to tackle a wide range of applications, from light surface preparation to heavy-duty blasting tasks. With adjustable settings and powerful performance, they're up to the challenge!

Q2: Are Ambica's machines suitable for indoor use?

Indeed they are! With their advanced dust collection systems and efficient operation, Ambica's shot blasting machines are perfectly suited for indoor applications. Say goodbye to dust clouds and hello to a clean working environment! Also check - Automatic Sand Blasting Machine

Q3: How easy is it to transport these machines?

Transportation is a breeze with Ambica's portable shot blasting machines! Thanks to their compact design and sturdy wheels, you can easily move them from one job site to another without breaking a sweat.

Conclusion

In conclusion, Portable Shot Blasting Machine Features | Ambica Enterprises represent a pinnacle of innovation and excellence in the world of surface preparation. With their versatile features, powerful performance, and user-friendly design, they're revolutionizing the way we approach surface restoration projects.

Whether you're a seasoned professional or a enthusiast, these machines offer unparalleled convenience, efficiency, and results.

So why settle for anything less? Choose Ambica Enterprises and experience the difference firsthand! Also check - https://sites.google.com/view/shot-blasting-machine-news/home

#shot blasting#shot blasting machine#shot blasting machine features#portable shot blasting machine features

0 notes

Text

ashley in freaky thursday: a bells hells charity one shot

#critical role#cr spoilers#cr lb#ygifs#ashley#freaky thursday one shot#the way this was such a blast and she is so beautiful 🫡on my knees

490 notes

·

View notes